Industry 4.0: It’s concepts and valuations

“New technology doesn’t become successful just because it is going to supersede the whole technology. When it replaces old behavior it becomes more successful” – Dr. Eliyahu Moshe Goldratt.

On 30th September 2020, an e-GL on Industry 4.0 was conducted. The eminent speaker Vijayakumar Ramachandran, an associate Vice President at Praj Industries Ltd. briefed about the four industrial revolutions along with the upcoming Industry 5.0. The degree of complexity increases with each industrial revolution.

The industrial revolution means doing economic activities concerned with the processing of raw materials and the manufacture of goods in factories in a smart and sustainable way. Industry 4.0 onwards the volume of manufacturing is going to be tremendous so the focus should be on processing.

In the first industrial revolution, the steam engines worked through the power of water. There was the first mechanical room in 1784.

The second industrial revolution was through the introduction of a division of labor and mass production with the help of electrical energy. There was the first assembly line Cincinnati slaughterhouse in 1870.

The third industrial revolution through the use of electronic and IT systems helped further automate productions. There was the first programmable logic controller, Modicon 084 in 1969.

Industry 4.0 originated in 2011 through the use of cyber-physical systems which helped increase the computing power.

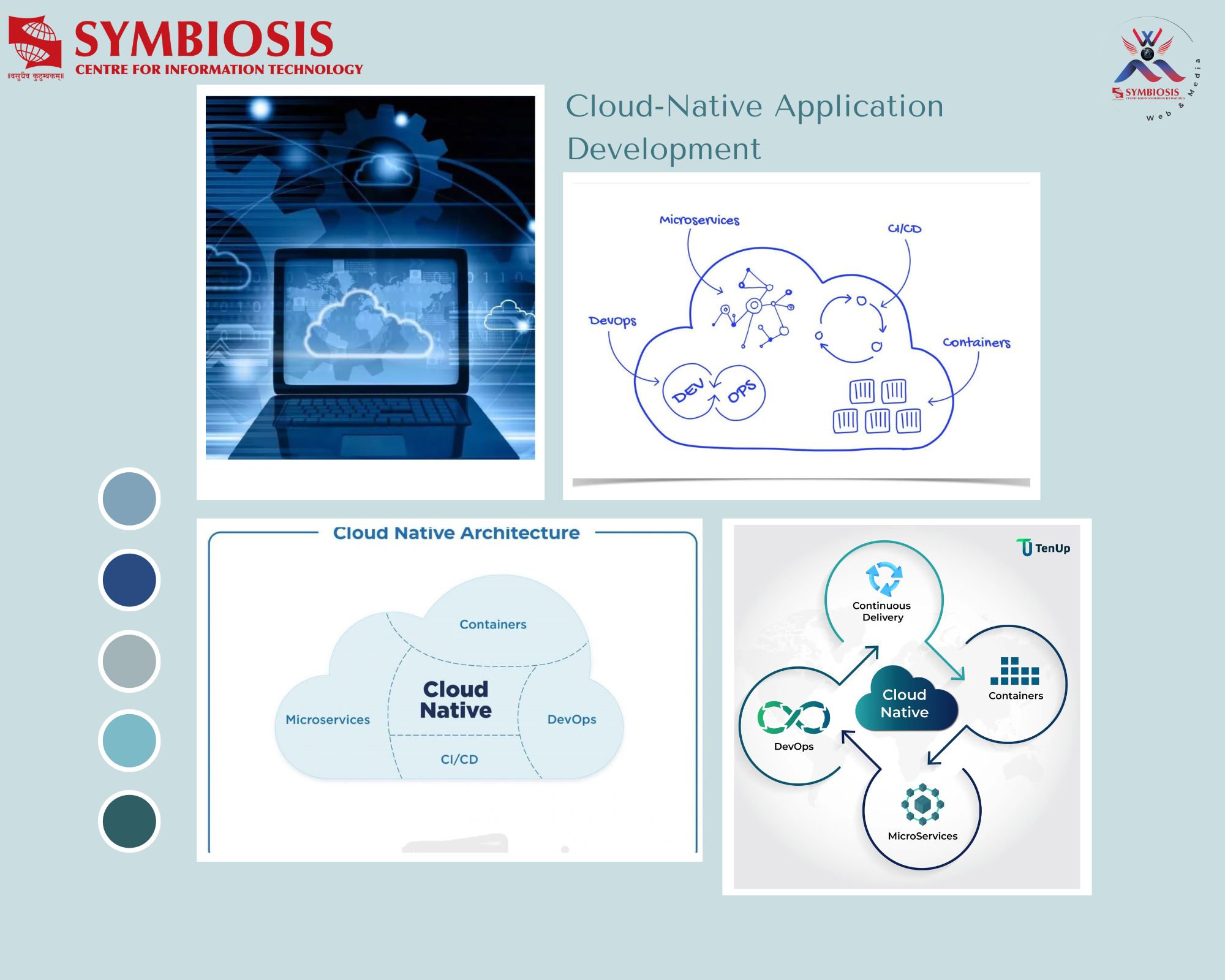

The remote performance monitoring services comprises of servers, applications training, identity and access management, micro-services, SMS, email services, etc.

Augmented reality helps semi-skilled workers learn before they actually go to the field. Advanced engineering like additive manufacturing like 3D printing, nanoparticles, and renewable energy helps increase efficiency.

The speaker spoke about the self-diagnostic plants which control motors, temperature, have sensors connected to the internet making the Internet of Things which is connected to cloud technology. The Digital Snaps provide data about different mounted instruments’ parameters at different time stamps. Data scientists need to superimpose different timelines to increase profits. Rules are defined and the rules take data from the Digital Snaps. This data is classified according to Machine learning algorithms. This technology is leveraged by Blockchain. There is an administration who accesses the information.

The degree of complexity is immense that it needs to be simplified for the end-users. There needs to be process engineering analysis, value analysis for the people working on the engineering level. For the person who is on the ground looking at operations, the information needs to be in the form of an SMS or email alert for actions to be performed. The managers need to have reports or dashboards to know how the plant is working.

The industrial benefits are that the company could be a market leader and also give value to the customers after using the insights to innovate and improve the products. The focus should be on scaling up the technology, making it modular and user-friendly to maximize the radius of the reach.

In the end, the speaker addressed the vast, upcoming opportunities in Industry 5.0 which is linked to technology business.